- Home

- Products

- Complete Packaging Line

- Type MK-420D Vertical Form Fill Sealing for Powdered Products

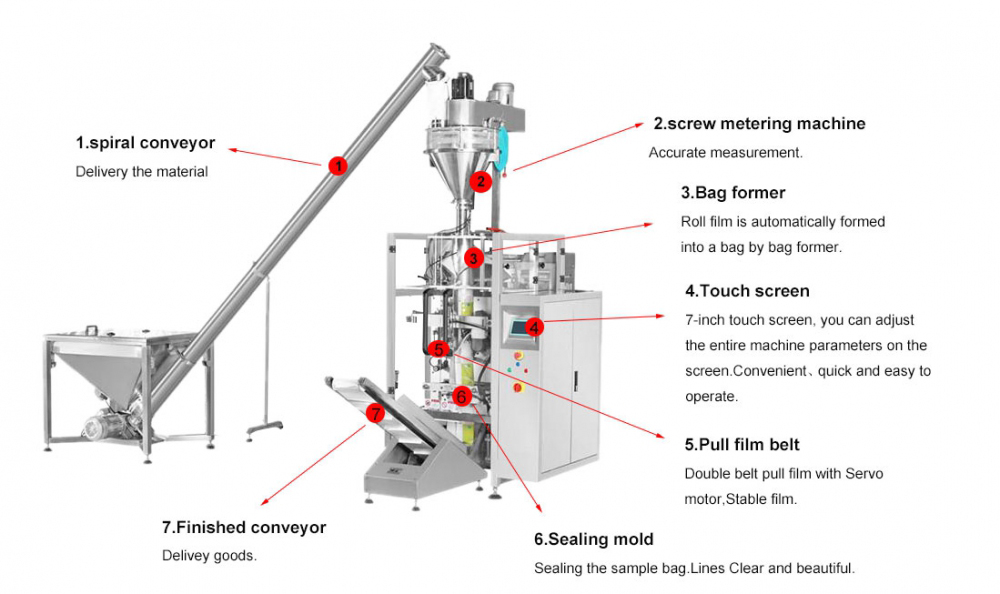

Type MK-420D Vertical Form Fill Sealing for Powdered Products

The Type MK-420D vertical form fill sealing for powdered products is equipped with an auger filler and screw feeder, ideal for the packaging of powdered products featuring -100 mesh like milk powder, albumen powder, coffee powder, flour, etc.

Packaging materials

OPP/CPP composite film, OPP/CE composite film, MST/P composite film, PET/PE composite film, aluminum foil.

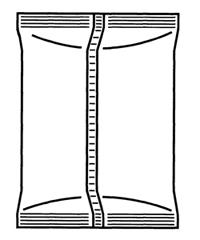

Packaging bag styles Flow pack wrapping

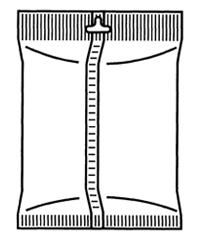

Flow pack wrapping  Hang hole bag

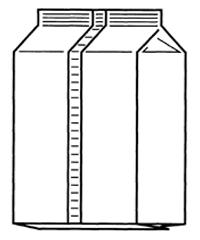

Hang hole bag  Gusset bag

Gusset bag

- Type: MK-420D

- Packing speed: 10-60bags/min

- Bag size: L:50-300mm W:80-200mm

- Measuring range: 10-2000ml

- Max film width: 420mm

- Film thickness: 0.04-0.10mm

- Air consumption: 0.4m³、min 0.6MPa

- Power source: 2.5KW/220V 50-60Hz

- Weight: 650kg

- Overall size: 2250x1670x2700mm

- Mitsubishi PLC control system and touch screen operating system allow for clear display of operational statistics and indication.

- High precision servo film feeding system guarantees smooth film conveying and accurate positioning.

- Intelligent digital temperature control system offers stable temperature difference control. A tooth sealing mould is equipped to ensure firm sealing.

- With automatic fault alarm display function, this vertical form fill seal packaging line will shut down immediately and alarm automatically once malfunction occurs.

- Packaging line feeder

- Finished package conveyor

- Weight checker

- Metal detector

- Ribbon printer

Other Complete Packaging Line

101, Block A, No.1742, Panyu Avenue North, Qiaonan Street, Panyu District, Guangzhou City, Guangdong Province.

Inquiry